Rubber Mats for

Railways infrastructures

Noise and vibration insulation for embedded tracks, ballast and concrete tracks

All products made from Natural Recycled Rubber

Noise and vibration insulation for embedded tracks, ballast and concrete tracks

All products made from Natural Recycled Rubber

Get it via email!

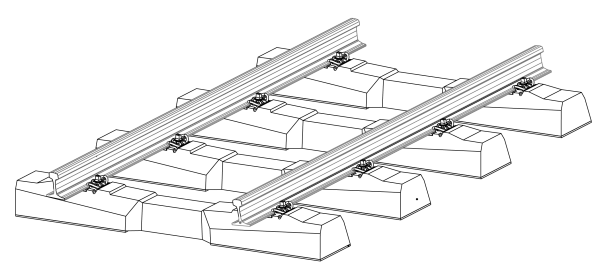

Under Sleeper Pads are specially designed for application under concrete sleeper for ballasted track. They can be manufactured with a specific non woven layer for assembly into wet concrete during the sleeper production process.

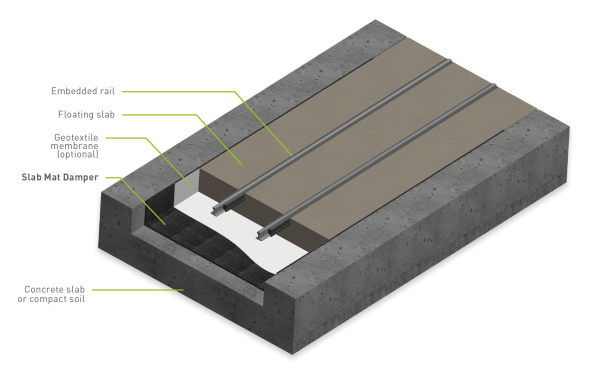

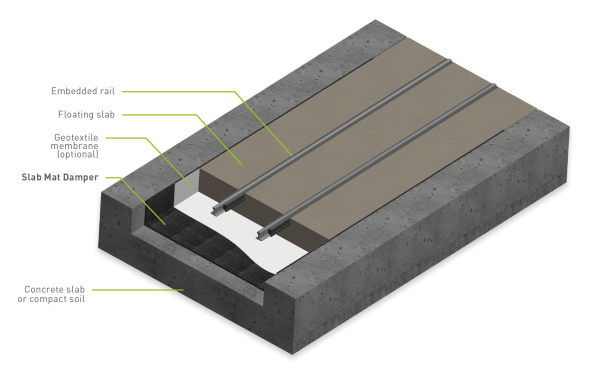

The Slab Mat Damper is a resilient mat made of natural recycled rubber that surrounds floating slabs of concrete railway tracks and significantly reduces the level of vibration in urban areas (-20 dB @ 63Hz)

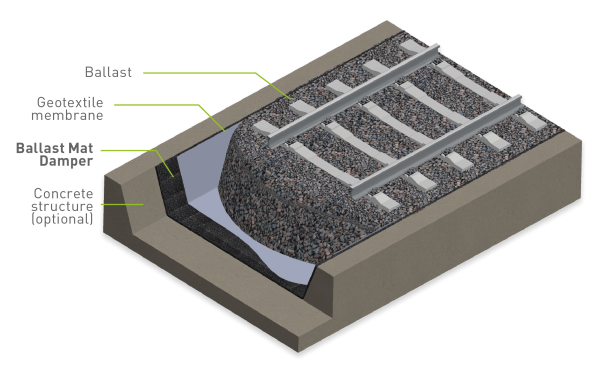

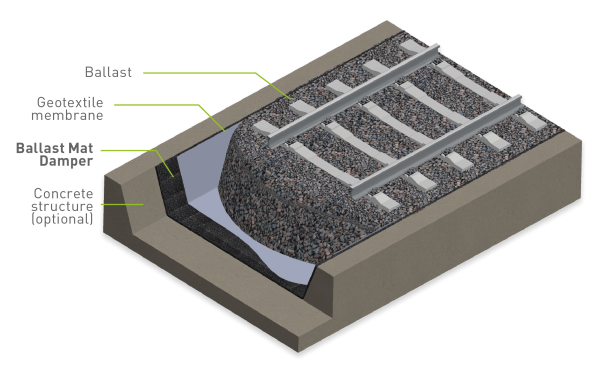

The Railmat Ballast Damper is an antivibrating mat in recycled rubber that is installed under ballasted tracks. It reduces vibration level of the ballasted track in urban areas (up to -20 dB @ 63 Hz).

Better performance with natural recycled rubber

Better performance with natural recycled rubber

Specific developments

Loss factor effect

Loss factor has a positive impact in the damping zone but a negative impact in the attenuation zone. A compromise has to be found in order to avoid too much amplification around natural frequency of the mass spring system and optimal attenuation performance in the critical frequencies.

Natural recycled rubber processed by RubberGreen gives optimal values of dynamic and static stiffnesses (designed upon track design) with an optimal damping loss factor.

USP

Under Sleeper Pads are specially designed for application under concrete sleeper for ballasted track.

They can be manufactured with a specific non woven layer for assembly into wet concrete during the sleeper production process.

Anti vibration performance

Natural rubber gives optimal properties for resilience, anti vibration performance with a low damping factor, fatigue and longevity resistance. It helps reducing the vibration noise of ballasted track in urban areas and/or can also increase the life cycle of the ballast. It also helps compensating reduction of the ballast thickness where it is not high enough. Finally it helps reducing impact force that structures may experience over time (such as Bridges).

Thicknesses, shapes and densities

The Ballast Mat Damper is available in different thicknesses, shapes and densities in order to address expected performances : low density and wavy shape for vibration insulation, higher density and flat shape for impact force reduction on structures. A geotextile membrane on top of the ballast mat damper is required in order to optimise product lifespan. It increases the resistance against ballast stresses and it protects the mat against dust from ballast wear.

Benefits

Anti vibration performance

Natural rubber gives optimal properties for resilience, anti vibration performance with a low damping factor, fatigue and longevity resistance. It helps reducing the vibration noise of ballasted track in urban areas and/or can also increase the life cycle of the ballast. It also helps compensating reduction of the ballast thickness where it is not high enough. Finally it helps reducing impact force that structures may experience over time (such as Bridges).

Thicknesses, shapes and densities

The Slab Mat Damper has a bottom wavy surface and a flat top one, which provides excellent resilience and an optimum dynamic behavior. This product can be installed in a single layer or double layers, either for prefabricated sections or “on site” when it comes to pour concrete on a railway track. It fits very well tramways or traditional railway tracks for high speed trains in urban areas. It is very protective to wet conditions thanks to its permeability and drainage features and is also resistant to frost and fatigue (tested according to DIN 45673-7).

Benefits

Our motivation and skills are driven by innovation and customer satisfaction

Design Our engineering department has a strong experience in designing sophisticated recycled rubber products which meet stringent technical requirements. Our team follows up scrupulously the industrialization of Under Sleeper Pad and the production of those pieces. We have the capacity to produce prototyping series or massive production series in a large range of dimensions (from 1 cm³ to dozens of dm³).

R&D program

RubberGreen constantly innovates through a number of research programs, some of which are supported by Wallonia Region. Those research programs enable us to develop:

- New formulation of recycled rubber with very high performance in traction (tensile strength 10MPa, elongation at break 300%)

- Under rail pad: develop a rail pad with more than 80 % of recycled rubber

- Under sleeper pad: develop an under sleeper pad with more than 90 % of recycled rubber

Engineering

Our engineers develop and set up themselves solutions to improve the production and the comfort of the workers. This is achieved by:

- Design of our own production processes/equipments and implementation in our plant with 3D CAD

- Workshop for tooling assembly and machinery construction with welding and machining equipment

Quality Management With our permanent care of client satisfaction, we manage to reach required specification and delivery time. It starts from the design of the product until the delivery and installation to customers. Our quality management system is mainly based on ISO 9001.

Route de Bavay 44

7080 Frameries

Belgium